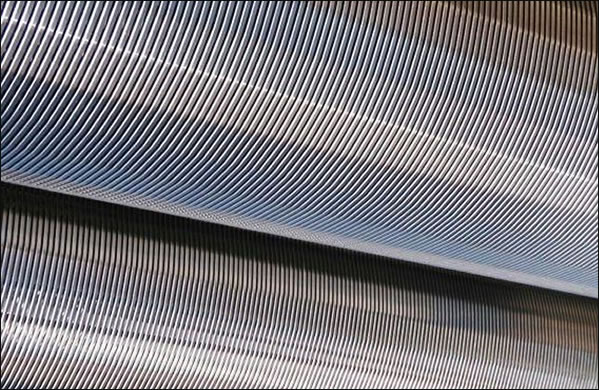

Wedge Wire Screen is widely used as well screen for groundwater and sand control applications. The V wire screen offers high strength, clog-resistant flow and precise filtration, ideal for deep well drilling, groundwater extraction and sand control in oil and gas wells.

Wedge wire well screens are available in stainless steel 304, 316L, or custom alloys.

Features:

- Continuous Slot Structure

The V-shaped profile wire creates a continuous slot that allows water to enter the well freely while keeping sand and fine particles out. - Non-Clogging Design

The outward widening slot prevents clogging by allowing particles to pass along the surface rather than getting trapped, reduces maintenance and prolongs the life of the well. - High Mechanical Strength

The welded screen construction is resistant to external pressure and collapse, ideal for deep well installations. - Corrosion Resistance

Typically made from 304, 316L, or Duplex stainless steel, wedge wire well screens resist corrosion from groundwater, seawater and chemical exposure.

304 Stainless Steel Continuous Slot Pipe Based Water Well Screens

Water well screens and water well conductor pipe and water well casing pipe

- 12″ (303mm) Austenitic Stainless Steel

(304 Stainless Steel) Water Well Conductor Pipe of 5.8 meter length with male threads from both ends and female coupling (minimum wall thickness should be 0.375″).

Quality of the conductor meets international standards API, ASTM, DIN or equivalent. - 8⅝” (219mm) Austenitic Stainless Steel

[304 Stainless Steel] water well casing pipe of 5.8 meter length with male threads from both ends and female coupling.

The minimum thickness of the pipe should be 0.296″.

Quality of casing pipe meets

international standards API, ASTM, DIN or equivalent.

A certificate of standard submitted. - 8⅝” (219mm) Austenitic Stainless Steel

[304 Stainless Steel,] FREE-FLOW continuous slot pipe based water well screens of 5.8 meter length fully compatible with casing pipe and with male threads from both ends and female coupling.

Slot size of the water well screen: 40.

Quality of screen meets international standards API, ASTM, DIN or equivalent

SS 316 Screen Well Pipe

- Pipe Size: 8″

- OD: 219.1 mm

- Length: 6 m

- Material: SS 316

- Slot: 0.25 mm

- Wire Wrap: 3.0+5.0 mm

- Rods: 3.8MM/48 mm

- End Connection: Threaded

- Collapse Strength: 399 PSI

- Tensile Weight:10.5 Ton

Stainless Steel Well Screen 4″ and 6″

- Screen diameter: 100 mm, 150mm

- Slot opening: 2.0 mm

- Length: 1m

- Well depth: 300 ft

- Delivered to Philippines

Well Casings & Screens

- Well Screens 16 inches x (3meter & 6meter)

20 Length Perforated Black Iron Pipe (B.I.) Casing

20 Length Galvanized High Carbon Well Screen Slot No. 40 – Pipe

20 Length Galvanized High Carbon Well Screen Slot No. 60 – Pipe

20 Length Stainless Steel Well Screen Slot 40 – Pipe

20 Length Stainless Steel Well Screen Slot 60 – Pipe

20 Length High Density Poly-Ethylene Well Screen Pipe (HDPE)

- Well Casing with 16 inches x (3meter & 6meter)

20 Length Spiral Welded Blank Casing – Pipe

20 Length Electro-Resistance Welded – Pipe

20 Length Seamless Pipe

20 Length Stainless Steel Casing Pipe

20 Length Fiber Reinforced Pipe (FRP)

Well Screen Liners

- 304 grade stainless steel (SS) well screens

- With 4-inch (101.6 mm) inner diameter (ID)

- Slot width: 0.010, 0.020, 0.040, 0.080-inch slot widths (0.254-, 0.508-, 1.016-, and 2.032-mm widths, respectively)

- In 10-foot (3.048 m) and 5-foot (1.524 m) sections

- 4-inch (101.6 mm) ID PVC solid casing in 10-foot (3.048 m) and 5-foot (1.524 m) sections

- 4-inch ID PVC end cap

- 4-inch PVC well plug

- All materials compatible/interchangeable for easily screw together

Stainless Steel Shutter Screen for Well Drilling

- Stainless Steel Metal Well Shutter Screen 10 Foot Length Louver Form

- Specifications: Stainless steel Shutter Screen for well drilling

- Specifications for the well screen are as follows:

- The casing screen is manufactured in accordance with applicable parts of ASTM A778

- Additions:

- Welding made by the dual submerged arc process using at least one pass on the inside and pass on the outside.

- Ten (10) foot lengths furnished.

- Circumferentially welded joints not permitted.

- Minimum wall thickness shall not be less than 5% of the nominal wall specified.

- The steel screen material: stainless steel Type 304.

- Well screen size: 12″ inside diameter and 3/16″ wall thickness.

- The shutter screen openings are machine made, horizontal to the axis of the casing and of a louver form with the aperture lacing downward.

- Shutter screen aperture .070″ and 96 slots per foot. The minimum open area 20in2 per lineal foot. Welding collars furnished and welded attached to each screen joint.

Stainless Water Well Screen

Specification:

- Water well screen 4″ Diameter

- Length: 4′

- Slot / gauze: 15, 18

- For neighboring wells

- Wells drilling depth: 60′

- Stainless screens to be attached to 4″ PVC casings.

- Screens delivered to USA

Wedge-Wire Screen / Basket

- Column internal screens – Inline Filter Basket

- Material: Stainless Steel

- Specification:

- Screen diameter: 100mm

- Length: 100mm, with a 150mm flange

Hastelloy Wedge Wire Well Screen Pipes

- Wedge wire Cylinder

- Material: Hastelloy / Duplex

- Specification: Nominal screen diameter: 100mm

- Length: 100mm, with a 150mm flange or nearest imperial equivalent.

- Delivered to

- Canada

4 inch Well Screen 316 Stainless Steel

- Material: 316 Grade SS

- Specification: Diameter 4 inch #7 well screen 316 stainless steel

- Length: 26 inches

- Hole size: #63 wedge wire, 0.007 slot size

- Screens delivered to USA

Stainless Steel Well Screen 14″ with 0.030 inch Continuous Slot

- Material: ANSI 304

- Specification:

- Diameter: 14 inch

- Slot size: 0.030 inch

- Thread: NPT

- Total length: 300 m

- Screens delivered to Peru

Slotted Wedge Wire Screens

- Material: Stainless steel, galvanized steel, alloy

- Construction: V shaped wire

- Slot: 0.4 mm

- Width: 1,5 mm width (W)

- Height: 1,8mm height (H)

- Open area: 20%

- Filter tubes total length 43m

- PVC pipes (casings): 75m long, diameter 305 mm or 323 mm, sedimentation tank 6m long

- Tubes threaded and coupled or welded connections

- Screens delivered to Serbia

Wedge Wire Screen Filters 6 inch for Wells Depth 650-1000 FT

Construction of Profile wire and support rods suitable for well depth around 200mtr-300mtrs/650-1000ft.

- 6″ Wedge wire screen

Material: SS304

Specification:

Slot 1mm

Plain End rings

Diameter: ID 153mm, OD 163mm

Thickness: 5mm

Open Area: 31%

Tensile Strength: 108 KN

Collapse Pressure-0.7MPa

- 6″ LCG, Slot 1mm, Plain End rings

ID-153MM, OD-165MM

Thickness-6mm

Open Area- 30%

Tensile Strength- 98.1 KN

Collapse Pressure-1.9MPa

8 inch SS 304 Slot 1mm V Wire Well Screen

- 8″, SS304, Slot 1mm

- Threaded Male/Female End rings

- ID-205MM, OD-219MM

- Thickness-7mm

- Open Area- 30%

- Tensile Strength- 225 KN

- Collapse Pressure-1.4MPa

- Threadse in line with API 5L Grade B Pipeline type threads meshing with screens.

- Supply to India

Wedge Wire Water Well Screen

- Tubular filter for water well installation

- External Diameter: from 8 up to 9 ½

- Welded to a Casing 9 5/8

- Slot opening: 1mm

- Material: stainless steel or Galvanized steel

- Edges designed to be welded

- Length: 150 m by each well

- Supply to Argentina

Constructive design for Well Screen

Technical data

Well screen

- Screen openings shall be uniform in size and pattern, and spaced approximately equally around the circumference of the pipe.

Stainless Steel Well Screen

- The well screen and fittings are fabricated entirely from stainless steel conforming to ASTM A312/A312M, Type 316 or 316-L, resistant to oxalic acid used to treat wells for iron bacteria. The well screen is of stainless steel with a rod-based keystone vee wire-wrapped continuous slot strainer equivalent to that manufactured by Johnson Screens. The well screen, pipe, and fittings have a minimum collapse strength of 90 psi. The screen, pipe, and fittings shall have a clear inside diameter of 7-7/8 inches.

Couplings

- Couplings for the stainless steel well screen shall consist of the same material as the well screen and shall be threaded, flanged, and/or fitted with a beveled welding ring. The couplings shall conform in design to the couplings recommended by the manufacturer of the well screen.

Perforations

- The 8 inch diameter well screen shall have a number 20 slot, 0.020 inch open slot. There shall be a total opening of not less than 60 square inches per foot of 8 inch diameter well screen.

Riser Pipe

- The relief well riser pipe material shall conform to the requirements specified for WELL SCREEN.

- The relief well riser pipe diameter and discharge details shall be as specified.

- Couplings to the well screen and between riser pipe sections shall be as specified.

- If the riser pipe is attached to the well screen by welding, the riser pipe shall be beveled to match the angle of the welding ring of the screen section.

Filter Pack

- Material for the filter pack around the riser pipes and screens shall be a dry processed sand composed of hard, tough, and durable particles free from adherent coating.

- The filter pack shall not be crushed stone.

- The filter pack material shall contain no detrimental quantities of organic matter nor soft, friable, thin, or elongated particles in accordance with the quality requirements in ASTM C33/C33M, Table 1 and Table 3, Class 5S, and in ASTM E 11, Table 1.

- The individual grading curves within the limits shown shall not exhibit abrupt changes in slope denoting skip grading or scalping of certain sizes.

- The filter pack shall meet the following gradation requirements:

U.S. Standard Percent By Weight

SIEVE NO. PASSING

- No. 4 100

- No. 8 94-100

- No. 16 32-88

- No. 20 5-35

- No. 30 0-18

- No. 40 0-3

- No. 50 0-1

Filter Pack Sampling and Testing

- All materials conform to the specifications specified to the project.

- The particle size distribution of the filter pack shall be sampled and tested in accordance with ASTM C136 and ASTM D 75/D 75M. Prior to delivery to the project site, at least two samples of material shall be collected and tested for every 750 tons (2000 lb) produced. Within 48 hours before being placed in the relief well to be back-filled, the filter pack shall be sampled from the material stockpiled at the project site. There shall be at least one particle size distribution test on the filter pack for every 25 tons (2000 lb) delivered to the site. A filter pack gradation test shall be performed in accordance with technical provisions herein specified.

Reports

- Reports shall include, for each relief well, logs of the boring.